Sole Systems 003: Midsole

Evolution of Cushioning II

(2000 - present)

Words by Rob Hallett

In the third part of our Sole Systems series, we pick things up at the start of the millennium to analyse the changes in attitude, desire to push boundaries and influence of sustainability in altering the way we feel and think about cushioning. We also take a look at the innovations happening around us right now and consider what they might mean for the future of footwear.

The New Millennium

Following on from the style over substance at the end of the last century, many of the big brands underwent an identity crisis and technology plateaued as a result. Mizuno’s Wave Rider midsole was designed to dissipate the energy quickly, but the plate was still surrounded by EVA and there were question marks about the system’s effectiveness. The turn of the millennium ushered in a wave of feel-good audacity and Nike took the chance to capture the mood with the introduction of the radical-looking Shox. Having been in development since 1984, the Shox system consisted of polyurethane columns that support the heel of the foot. Attempting to absorb heel strike impact and boost speed, Shox was designed to mimic the bounce of indoor running tracks while retaining the firmness needed to change direction. Marketing the Shox became a breeze thanks to Vince Carter’s Olympic dunk over Frédéric Weis, and the line’s commercial success continued for the next few years.

Fig 1. Nike Shox worn by Vince Carter

Running Free

As scientific interest in the function of footwear increased, the industry gradually learnt of its own shortcomings. Biomechanics research failed to confirm that pronation increased chances of injury and studies found that feet grew stronger when unaided by supportive shoes. The realisation that overprotective footwear might have an adverse effect on muscles acted as a wakeup call for brands to go back to the drawing board. After Professor Lieberman popularised the idea of natural running that didn’t need to be corrected or altered, brands changed their intentions to work with - rather than against - the organic movement of the foot. It was in 2004 that Nike’s Free technology brought about major change in the perception of cushioning, as they attempted to recraft the outsole into highly-bendable segments that closely match muscle movement when running without shoes. The 3.0 and 5.0 iterations became the most popular in the range, and after a short hiatus are still in production today. Vibram’s notorious FiveFingers took this to idea to its epitome, as the glove-for-your-foot concept forced wearers to tread more lightly and hold a quicker, more natural stride.

Fig 2. Vibram FiveFingers

An Eye on Sustainability

In 2008, Brooks Running introduced the first-ever biodegradable midsole by adding a non-toxic and natural additive to their existing compound. Brooks BioMoGo encourages anaerobic microbes in landfill to eat away at the material up to fifty times faster than traditional EVA, breaking down into usable nutrient by-products for plant-life and reducing landfill over time. With EVA remaining the compound-of-choice for everyone, Nike debuted Lunarlon, their own updated version of Phylon. Lunarlon provided a softer and more responsive foam than EVA, but needed to be surrounded by a protective layer of harder foam coming into contact with the ground. These two layers were glued together, increasing the weight of the unit in order to make the dual-density midsole possible and providing a less-than-perfect solution.

Fig 3. Brooks Cushioning System

Minimalism and Smart DNA

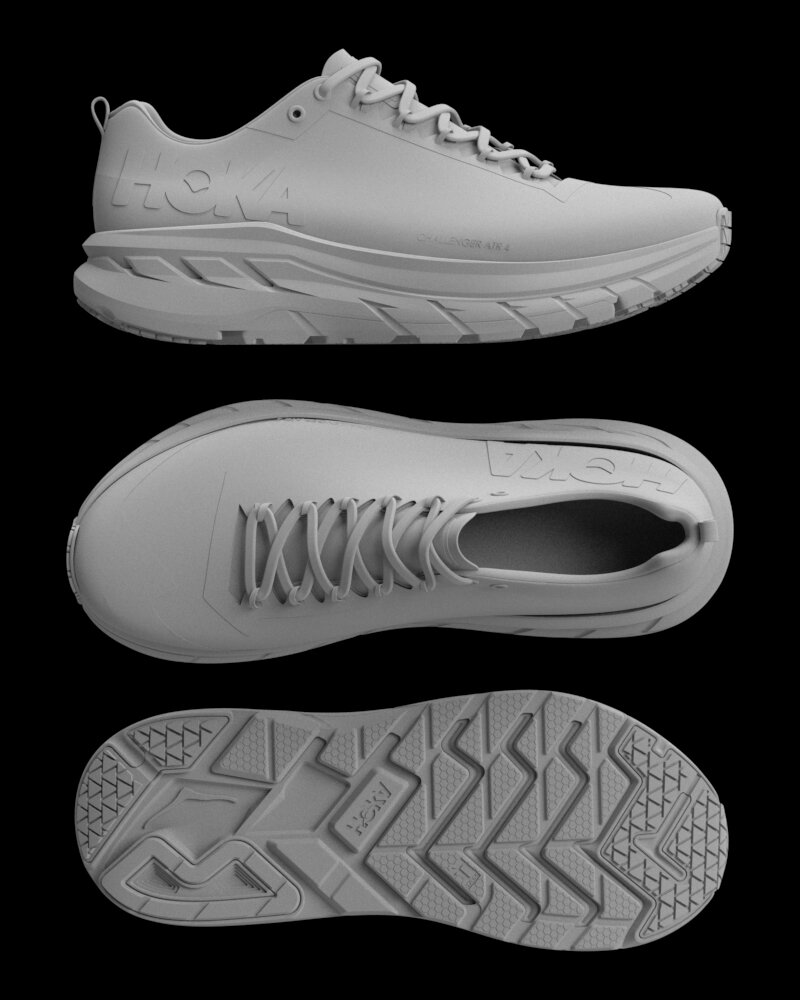

Tailoring cushioning to the individual level made a huge leap a year later when Brooks revealed their DNA smart cushioning system. The gel-like technology within the BioMoGo midsole included several pockets of a highly-viscous non-Newtonian fluid. The liquid doesn’t obey the usual laws of compression, and the material is able to adapt its viscosity when placed under intense force. The DNA system contains molecules connected by flexible strands when left untouched, but that grow in thickness and stability when put under pressure. The result of this is that the material will change to become more liquid or solid based on the levels of stress placed upon it, and can therefore adapt to the height, weight and stride of the user. As the industry nose-dived towards all-out minimalism, two former Salomon employees jumped ship to start their own company focussed on footwear with maximalist cushioning. Hoka One One was born. While everyone else was intently focussed on making shoes thinner, lighter and more streamlined, Hoka set out to go against the grain and produce a line of running shoes with an extra chunky midsole.

Fig 4. Hoka One One 3D CAD

A Boost of Energy and a Spring In Your Step

For Adidas to return to the top of the footwear food chain they needed something new, effective and marketable. The chemical industry again provided the answer as BASF supplied their closed-cell particle foam ‘Infinergy’ for Adidas to use. Making its 2013 debut in the Energy Boost running shoe, the highly-elastic foam consists of compounded and expanded TPU capsules fused together. The main advantage is its recovery ability; even under a continuous and stressful load it is able to maintain its resistance in -20 to +40 degrees Celsius. Reducing the amount of energy loss enables the wearer to give less effort and gain the same results. In other words, you could run faster or further with the same amount of exertion. Partial to the success of Boost at commercial level is that which also made Nike Air so popular in the 90s; the visible technology provided a visual cue that the product was safe, as consumers wanted a more transparent conversation about what they were buying. While it failed to grasp headlines in the same way as Boost, Adidas’ other midsole reveal that year is worth a mention if only for its prosthetic appearance. With questions over its weight, ability to handle backwards running and aesthetic barrier to adoption, the Springblade has since disappeared from the Three Stripes’ directory.

Fig 5. Adidas Boost

The Pinnacle of Air and a Foam Reaction

Billed as the ‘pinnacle of Nike Air’, the Vapormax was revealed in 2016 as the first foamless unit in the line with air bubbles acting as the entire midsole. Maintaining its standalone form through elasticity with a little added outsole traction, Vapormax stole all the headlines as a lifestyle trend but failed to make a lasting impression compared to performance foam solutions. Puma, New Balance and Asics soon joined in with their Ignite, Fresh Foam and FlyteFoam respectively, and as Under Armour enlisted Dow Chemical to add their Hovr system a little later it became clear that the era of foam was here to stay. While it would be unfair to say that Nike struggled to compete with Boost technology, they certainly weren’t handed any favours as Adidas bulldozered their way through releases with a roster that included Pharrell, Kanye West and Raf Simons. Boost was the cornerstone of Yeezy footwear during its early years and West’s covetable co-sign fuelled the hype like no other. In 2017 Nike unveiled their solution. Going by the name of React, the material provided a one-piece foam with maximal cushioning that solved the dual-density problem of the earlier Lunarlon. Scrapping EVA in favour of a thermoplastic elastomer (TPE) base, React’s alternative chemistry allowed for an adjustment in cushioning across different areas of the shoe.

Fig 6. Nike React Element 87

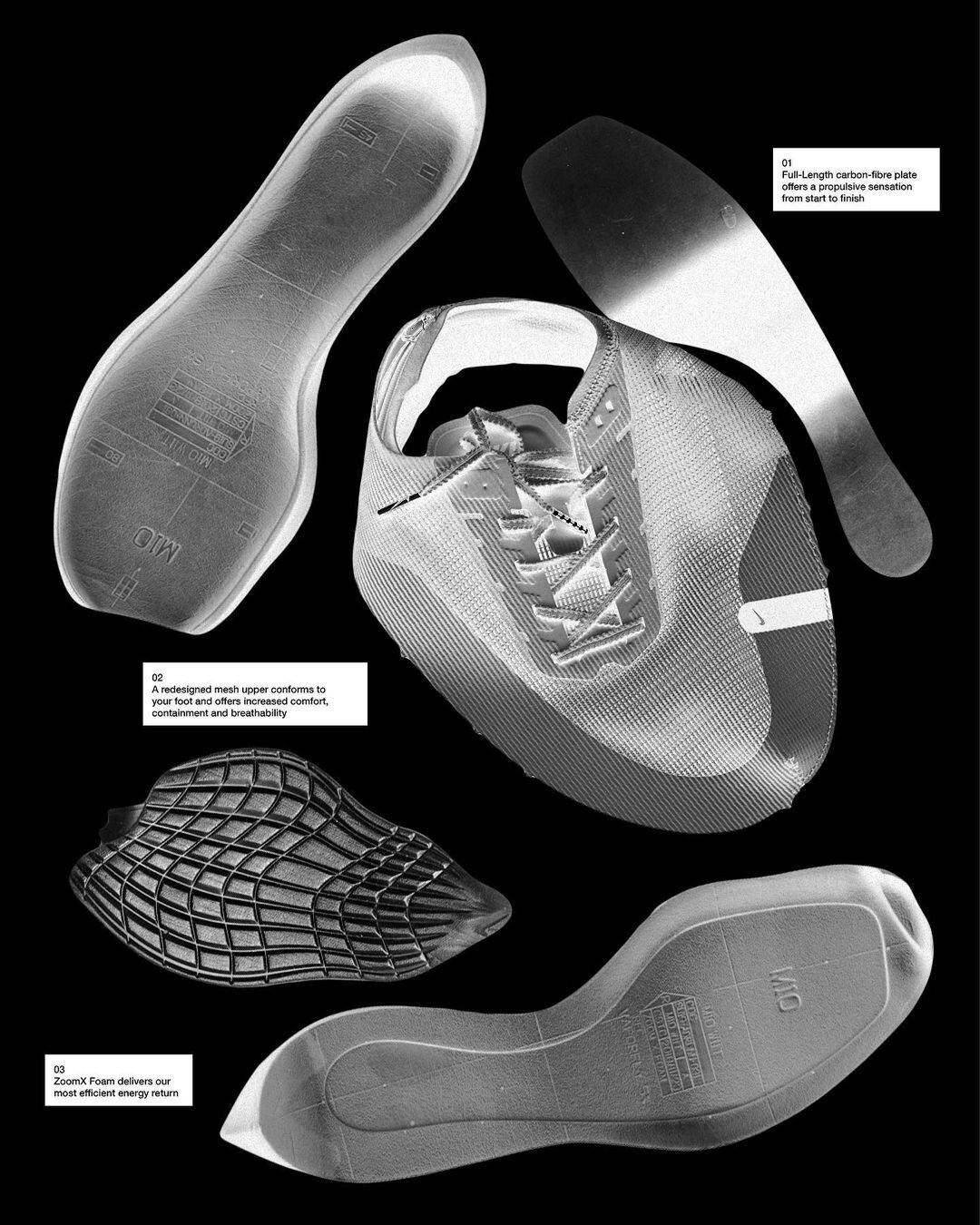

Breaking2

In the spirit of ambition, Nike continued their midsole development to expand the horizons of human performance. Equipping runners to complete a marathon in under 2 hours, the ‘Breaking2’ project had three elite runners don Nike’s Vaporfly Elite for the endeavour with Eliud Kipchoge coming 26 seconds shy. Two years later Kipchoge finished in 1:59:40, crossing the finish line in a prototype of the Alphafly NEXT% and cementing the company’s place in record-breaking history thanks to two visible Zoom Air pods and the ZoomX foam of earlier models. Pebax - the thermoplastic that makes the ZoomX unit possible - is an intensely springy lightweight foam that channels energy into your toes as you leave the ground. Using a huge amount of the compound reduces vibration greatly, but the instability it bestows requires a longitudinal plate to act as a chassis. The trade-off here – as with all lightweight products - is durability. While the carbon fibre plate is able to stabilise the foam it can’t extend its ability to withstand wear and tear. This doesn’t matter much when you’re trying to break records, but it isn’t a viable solution in the longer term. With Alphafly design cues hitting other Nike footwear such as the Zoom Double Stacked and the ISPA Road Warrior, we can expect to see progression here as the Swoosh explores combining and layering their range of technologies to reach new heights.

Fig 7. Nike Vaporfly NEXT% 2

Renew, Reuse, Recycle

The ongoing race for the next big breakthrough has undoubtedly had detrimental effects on the environment, with chemical use and overproduction leading to a multitude of waste. While there is still a way to go in terms of sustainable footwear, developments are in place that seek to turn waste into new product and bring a second life to material resources. Sustainable material company Bloom are spearheading an algae-based foaming process, using nuisance plant material to create countless products from Merrell, Etnies, Reebok and most notably the Yeezy Foam Runner. 2019 brought about Converse’s Renew project where they were able to iterate their iconic Chuck Taylor using recycled plastic bottles, upcycled post-consumer denim and a speckled-grey cotton using their own production off-cuts. The range now includes countless midsole units made with recycled rubber scraps from other shoes and have a flecked appearance shared with Nike’s Space Hippie line.

Fig 8. Converse Renew

Where Do We Go From Here?

With a long history of teaming up with chemical manufacturers and a reputation for encouraging over-consumption, the footwear industry has plenty of critics and work to do in order to silence them. Offering a glimpse of the future, the Adidas x Parley ALPHAEDGE 4D utilises Ocean Plastic for a 100% recycled marine debris upper and Adidas’ 3D printed sole unit. While the cushioning system here isn’t currently a sustainable option, the modelling eradicates the waste you generate from cut-and-sew methods and there’s no reason why the entire makeup can’t be made from recycled materials. The Three Stripes’ other recent team-up with Allbirds resulted in the lowest carbon footprint of any shoe ever, as they tapped into the New Zealand brand’s sugarcane-based SweetFoam sole to achieve an outcome of under 3kg CO2 per pair. The race for performance and the race to sustainability are currently side-by-side and occasionally swapping lanes, but they are inevitably on a collision course for the ultimate industry crossover. We are hopefully headed for a sustainable shoe that also accelerates performance higher than that which is currently being achieved, as brands continue to use their infrastructures to nurture their environmental responsibility and develop new materials and techniques along the way.