CAMPERLAB by CONCEPT(K)

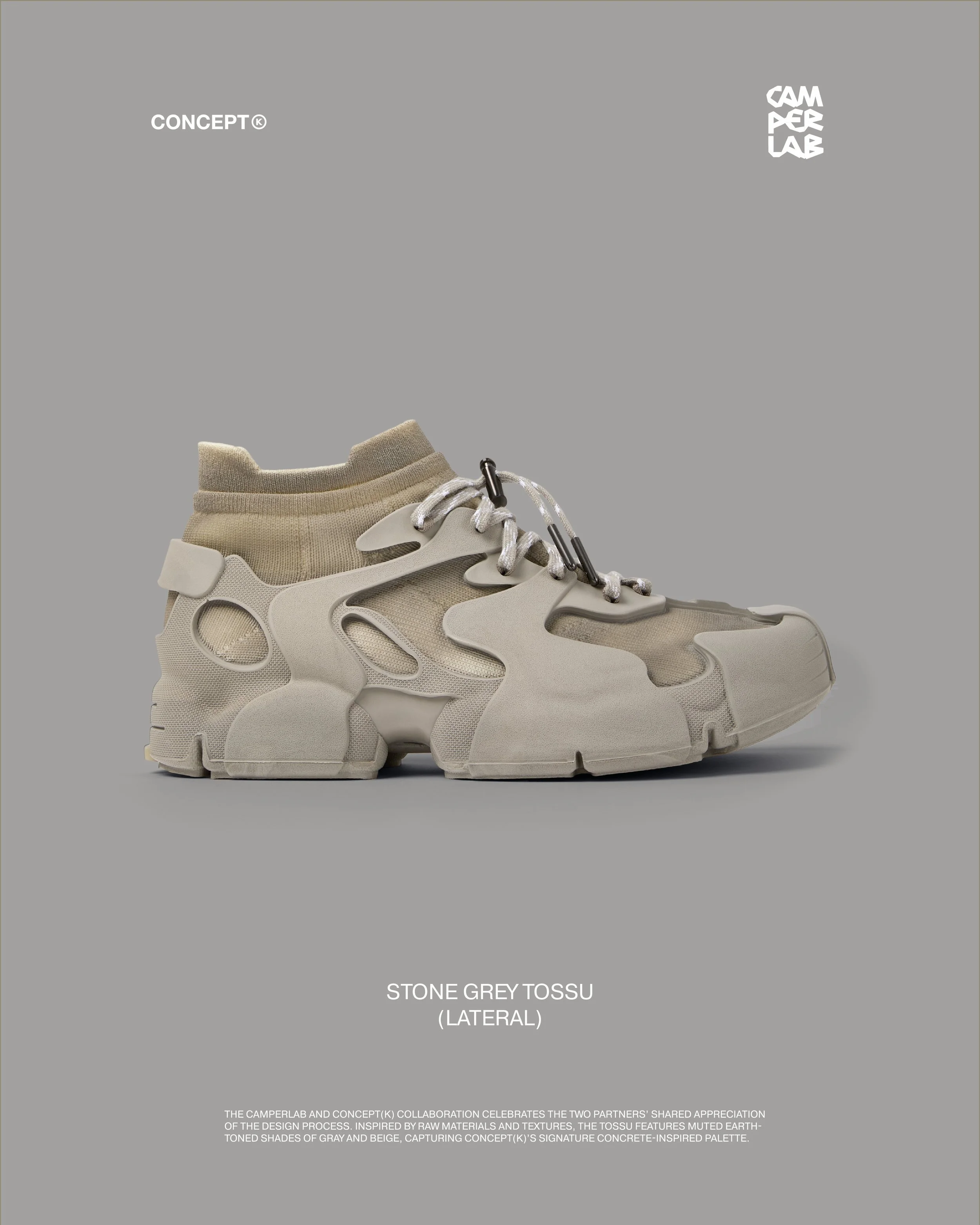

STONE GREY TOSSU

Fusing Process and Form

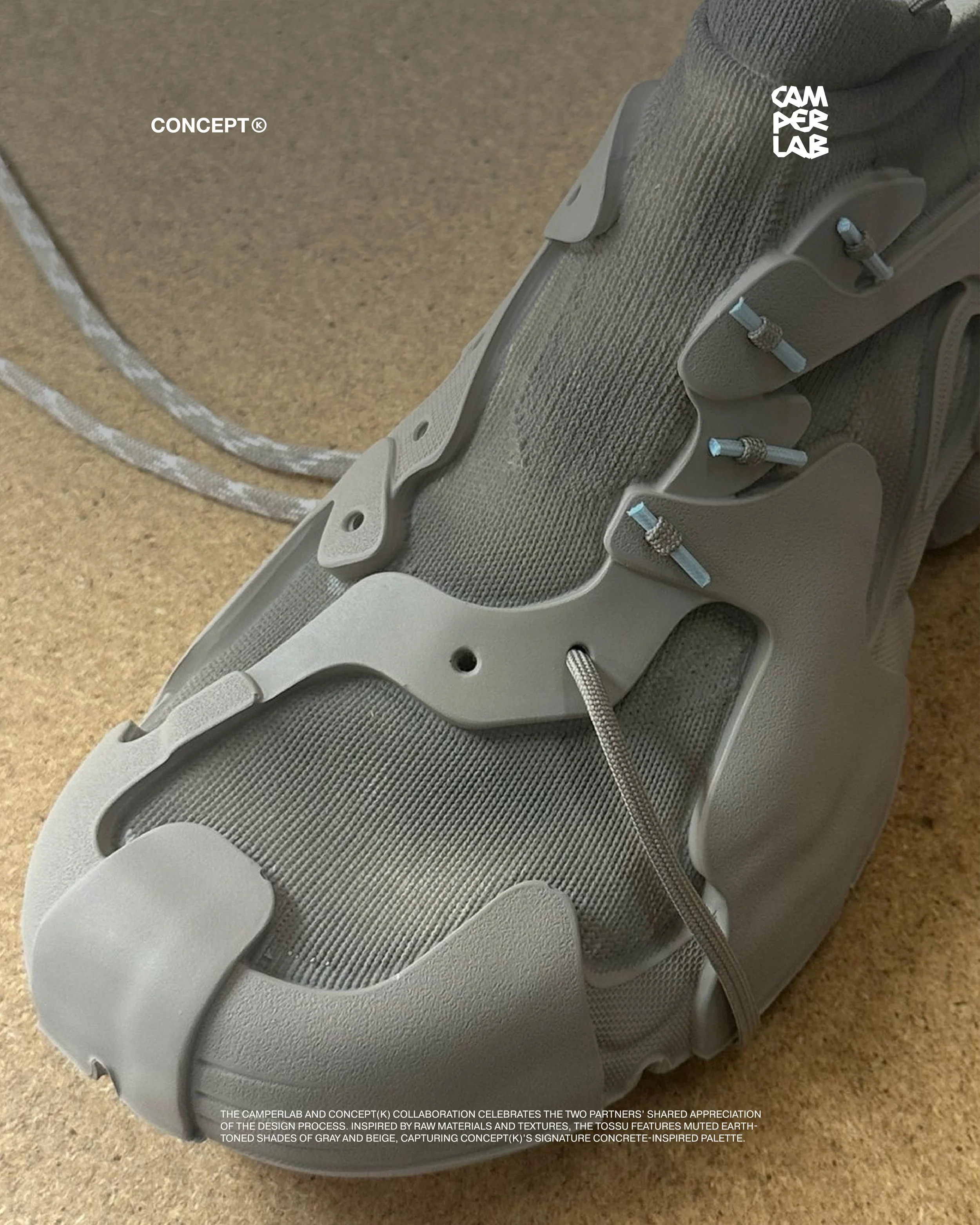

CONCEPT(K) has partnered with CAMPERLAB to interpret the Tossu, a culmination of our shared dedication to process, materiality, and design innovation. The model merges two industrialised techniques: knitting for comfort and fit, and 3D Bonding to shape complex organic forms. Featuring a moulded cage with open windows that reveal a textured, stone-washed interior reminiscent of concrete, the design delves into the interrelation of form and make while reflecting themes of sculpture, raw materials, and aggregates.

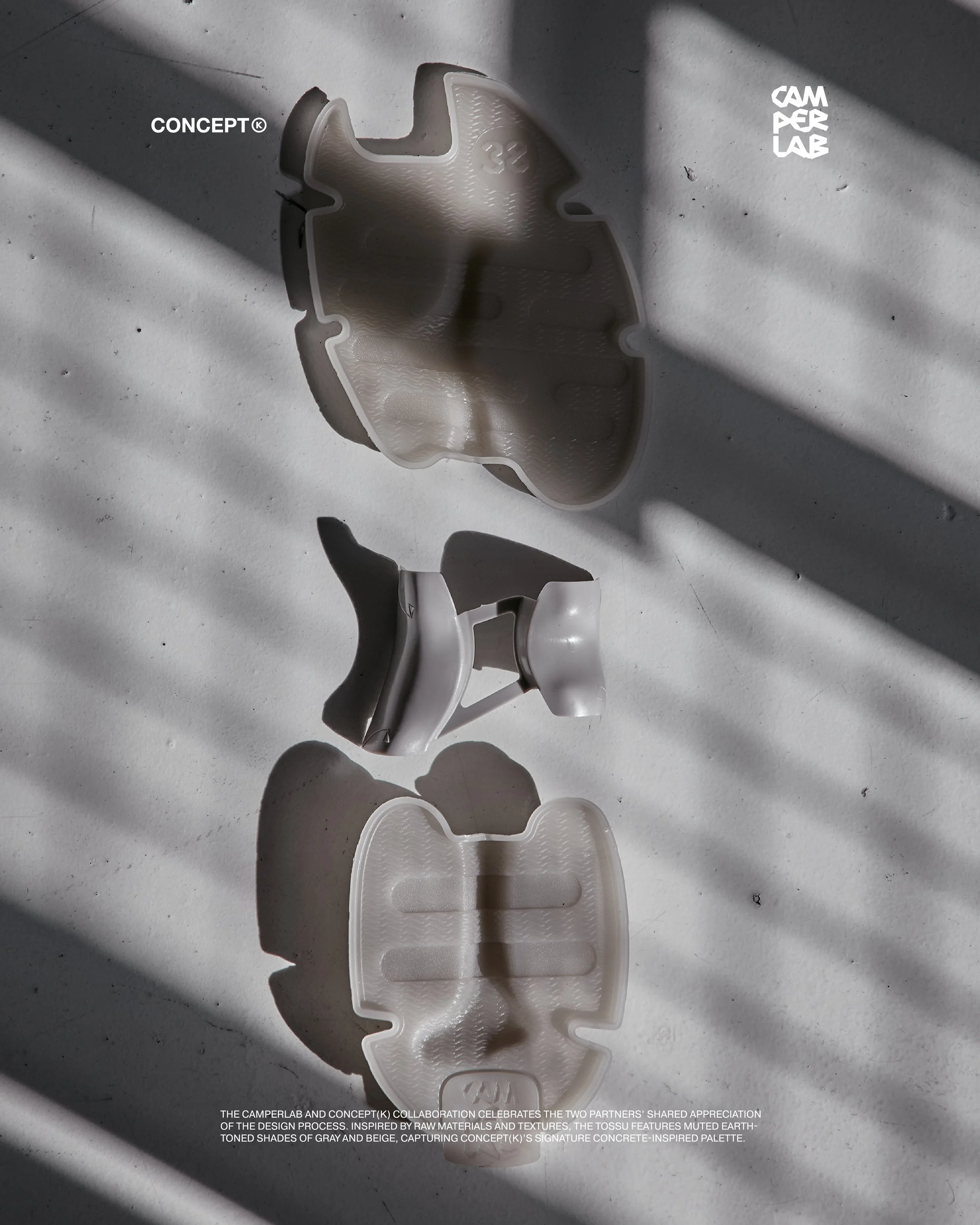

Central to the Tossu model is the 3D Bonding process, an innovative production technique that seamlessly fuses the sole to the upper without the need for glue, resulting in zero waste. Initially developed as a pragmatic industrial method by contemporary footwear brands, this bonding technology has been taken to new levels by CAMPERLAB, using it to fill a lineup gap with a bold, unapologetic sneaker. The resulting form is reminiscent of liquid flowing around the upper and outsole, emitting an industrial and futuristic aesthetic that is inherently shaped by its method of make.

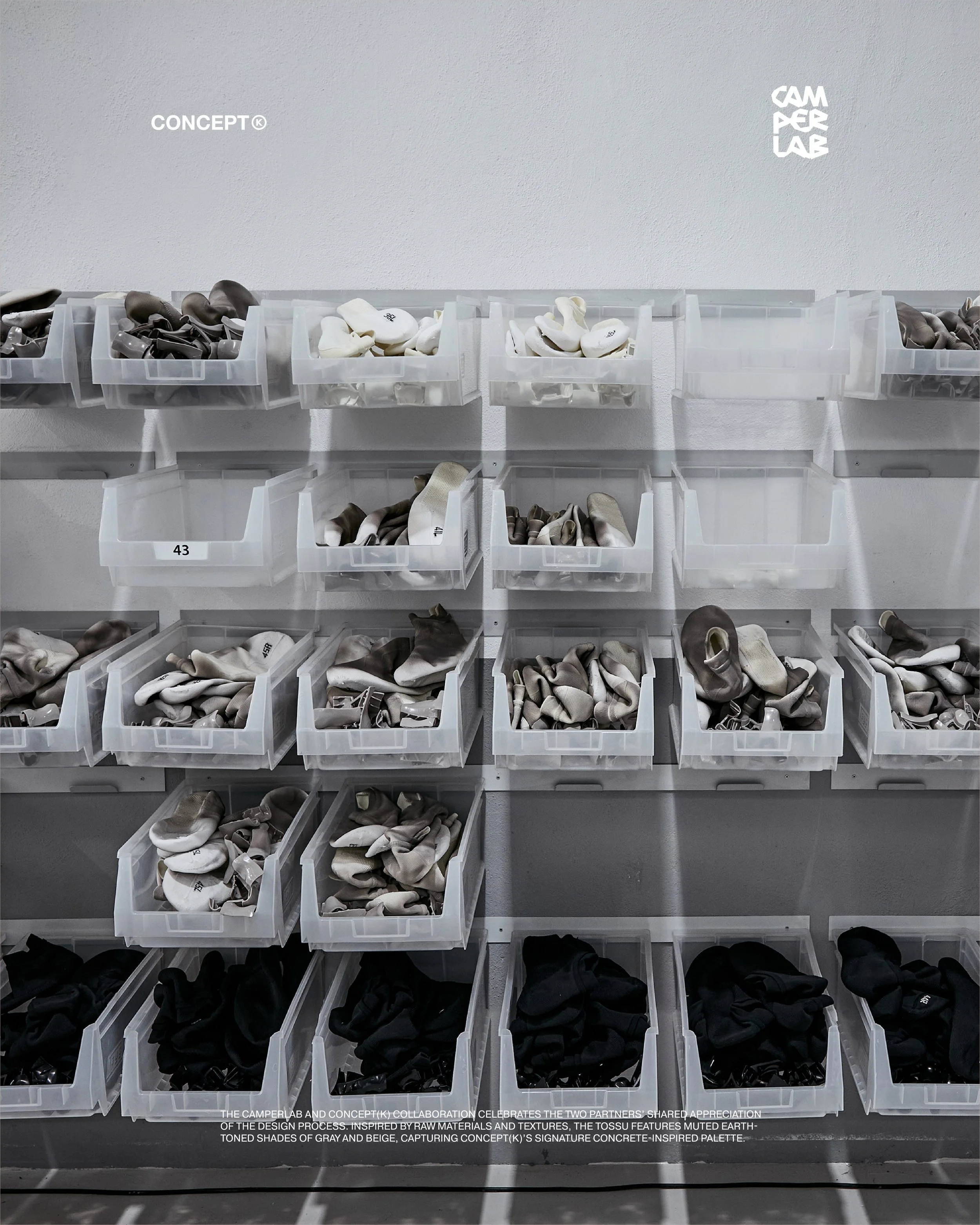

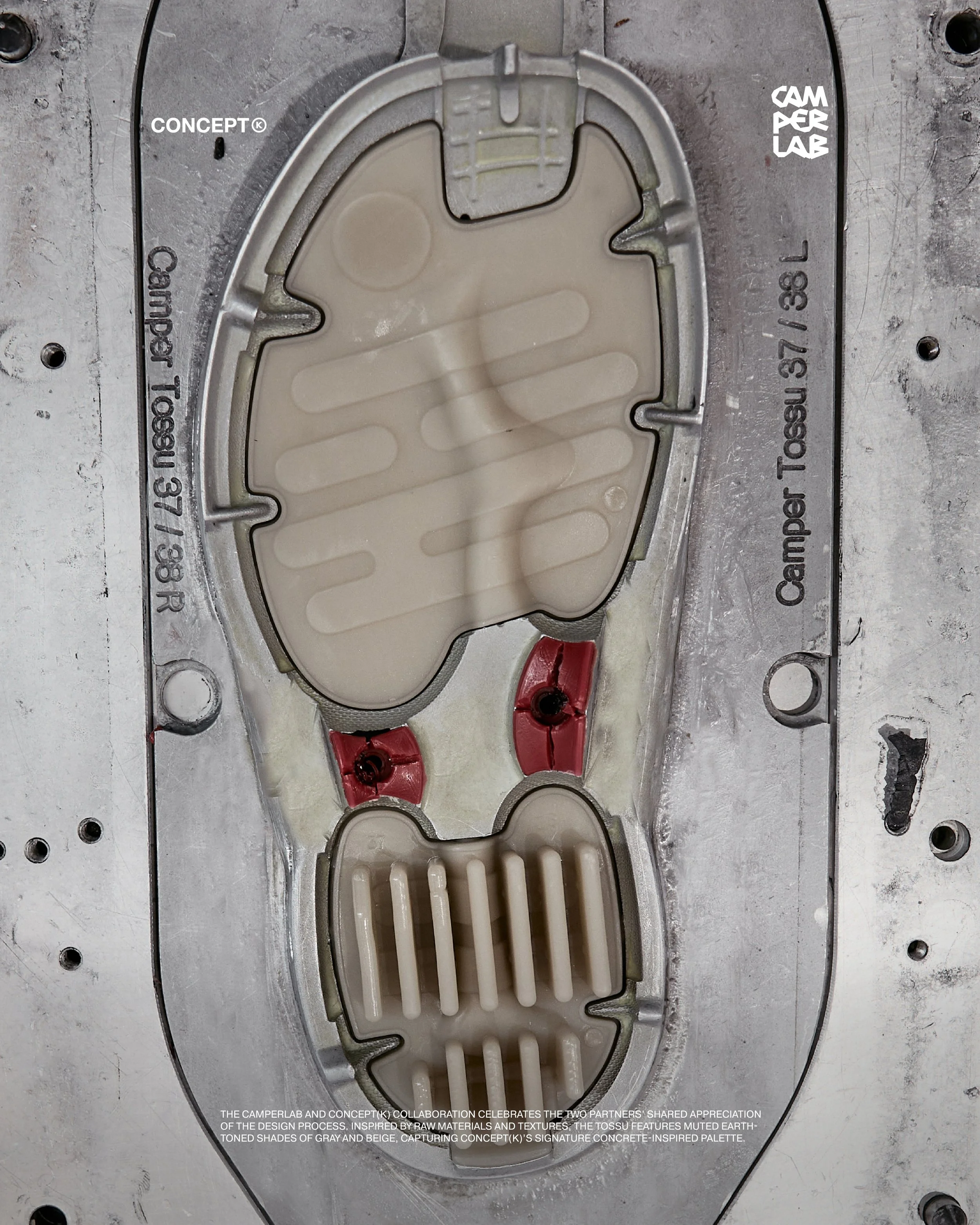

The 3D Bonding process, integral to CAMPERLAB’s brand ethos (and well-aligned with its B Corp status), involves injecting molten materials such as TPR, PVC, or PU into a mould cavity to create the desired shape, which in the case of the Tossu, fuses a moulded rubber outsole with a water-repellent 3D-knitted sock made from recycled polyester. The process begins with preparing the finished knitted upper on a last, which is then enclosed within a two-piece mould that forms the cavity for the outsole. Molten material is injected into this cavity, and as it cools, it bonds strongly with the upper. Often powered by electricity, this method is enhanced by digital sensors that ensure high precision without the need to open the moulds, making it both energy-efficient and highly consistent.

Beyond its practical advantages, the 3D Bonding technique offers designers a more fluid and exploratory creative process. For CAMPERLAB’s original Tossu, designed by Eliška Horčíková, this began with a hands-on approach, where EVA was layered onto a lasted knitted sock and then sculpted into shape using a drill. This method provided greater freedom to experiment with form and volume, allowing the design to evolve intuitively. It enabled the team to refine curves and shapes with a sculptor’s precision, free from the constraints typically imposed by traditional methods like stitched uppers and glued outsoles.

The integration of this technique with the design of the Tossu speaks to a symbiotic relationship between process and form, making the model an ideal canvas for CONCEPT(K) to expand on. It celebrates materiality while highlighting CAMPERLAB’s innovative manufacturing process. Crafted entirely in Europe by four skilled workers in a dedicated hangar, the Tossu minimizes labor costs and environmental impact by reducing the need for manpower and eliminating the need for distant production and transportation.

Our CONCEPT(K) iteration, inspired by raw materials and textures, exhibits muted Earth-toned shades of grey and beige that draw from our signature concrete-inspired palette, embodying our philosophy of merging diverse elements into a unified whole. The shoe’s proportional design harmonises industrial accuracy with sculptural form. Incorporating elements like concrete and stone-washed textures, the project weaves a narrative that bridges the raw, the refined, and the mechanical, encapsulating the shared design ethos of both brands.